There are various steps to creating climbersoap

Making the molds

- Make a container that fits the climbing hold of choice.

- Place the climbing hold and then pour the sillicone on top. This takes 8 hours to solidify

- Remove the hold from the solidified sillicone

The soap mixture:

- Preparing my soap mixture, which consists of biological coconut oil as the main ingredient.

Coconut oil is known for its nourishing and moisturizing properties, making it an excellent choice for soap making.

- I carefully measure and mix the coconut oil with the lye and water to initiate the saponification process.

Saponification is the chemical reaction that transforms the coconut oil into soap.

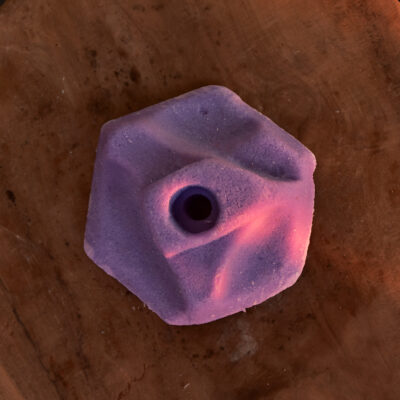

- After that I add essential oils and natural pigments.

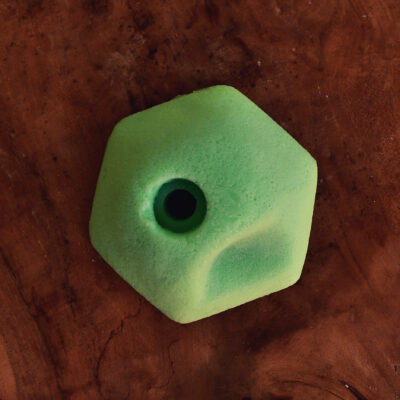

- Once the soap mixture reaches the desired color, smells and consistency, I pour it into silicone molds.

- The soaps can be removed from the molds after 24 hours.

The silicone molds are flexible and enable easy removal of the hardened soaps.

- The soaps are then curated for 4 weeks to reach pH neutrality.

What sets my soaps apart is that I create them with a superfat percentage of 20%. This means that my soaps contain a higher amount of unreacted oils or fats than what is necessary for the saponification process. This excess oil acts as a moisturizing factor, ensuring that my soaps provide gentle and nourishing care for the skin during use.

TLDR; by using biological coconut oil, crafting my own silicone molds, and formulating my soaps with a 20% superfat, I can create customized and moisturizing soaps that cater to the unique needs of individuals looking for a safe and gentle cleansing experience.